get started

Let's Talk.

Interested in learning how press can fit into your business?

Sales and Support:

833-757-3278

get started

Interested in learning how press can fit into your business?

Sales and Support:

833-757-3278

get started

Interested in learning how press can fit into your business?

Sales and Support:

833-757-3278

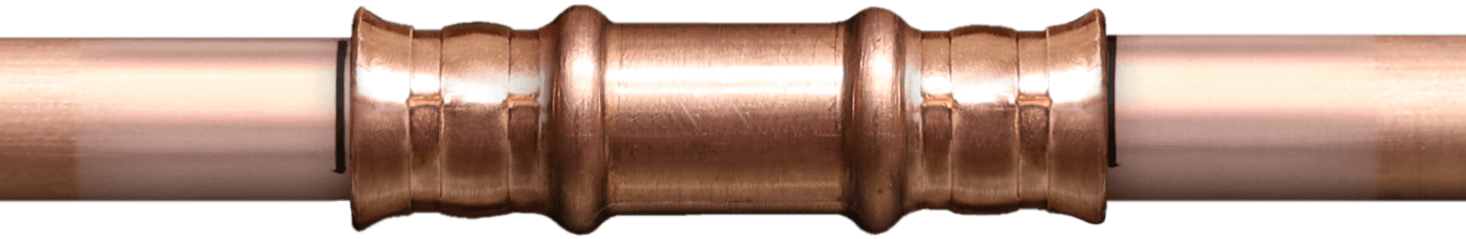

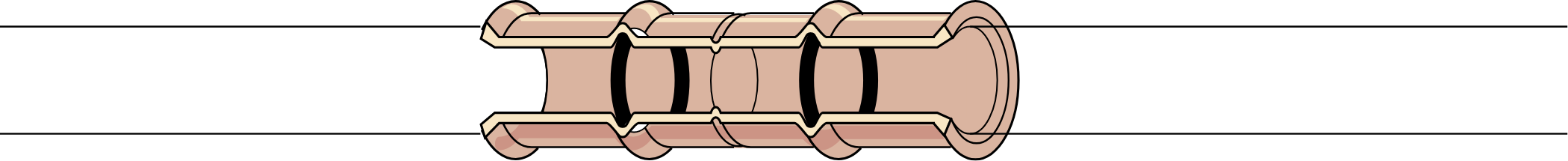

Think of your business as a big tool chest. You have to work smarter every day to fill it with the right products, the right tools and the right people for every job. When making reliable HVAC pipe connections, press fitting technology belongs in your tool chest. With greater efficiency, consistency and safety at every connection, press technology is the next tool of the trade and a perfect fit for greater productivity.

watch video

Press fitting installation is 60% faster than brazing. With no need for heavy brazing equipment and processes, press connections can be completed in 10 seconds or less.

With 60% faster connections the time savings really add up. Less labor and less material boosts your productivity and profitability.

Tubing prep is similar to brazing, but the press tool does the connection work in just seconds offering a comparable and permanent mechanical connection.

With millions of connections already in service worldwide, press fitting is a proven technology. This precision-engineered process ensures consistent quality at every joint. And unlike brazing, each connection is backed by a manufacturer's warranty.

Press Fittings are installed with a tool and jaw, virtually eliminating the chance of human error and resulting in consistent, repeatable connections every time.

Press technology is flameless and eliminates the need for on-site fire safety teams, flame precautions and permits required when using a torch. All of which add people, time and cost to the bottom line.

Press Fittings never require the use of an open flame, which eliminates a source of hazards when working in tight areas or near flammable materials.

It’s not just eliminating fire spotters and permits, not brazing means there is no need to nitrogen purge and no need transport gas and other equipment to the job site.

- Ryan O’Grady

- Robert Swieconek

- Alex Bishoff

- Lutz Heating & Cooling

Start your project

Interested in learning how press can fit into your business?

Sales and Support:

833-757-3278